RIB & BLOCK

We proudly supply Rib & Block Garden Route, including Mossel Bay, George, Groot Brakrivier, Knysna, Oudtshoorn, and surrounding towns.

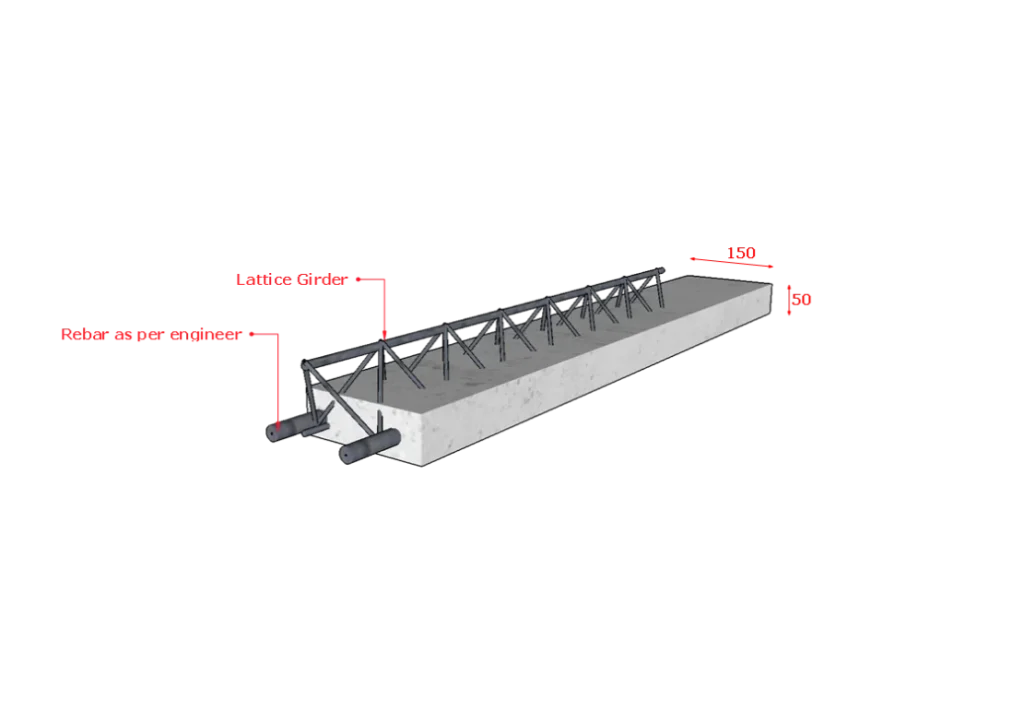

We manufacture all the components for the Rib & Block system which is a modular system used for building concrete slabs for newly built homes. It is a very economical system as no conventional formwork is required prior casting the concrete slab. A lot of effort and time is saved when comparing the rib and block system versus the conventional systems.

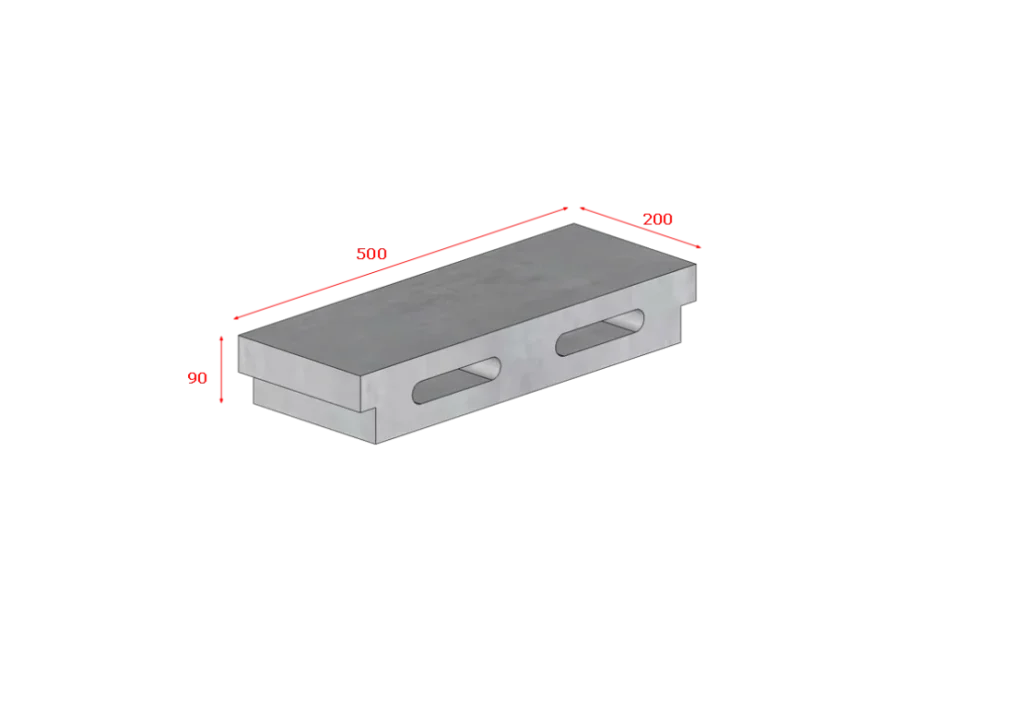

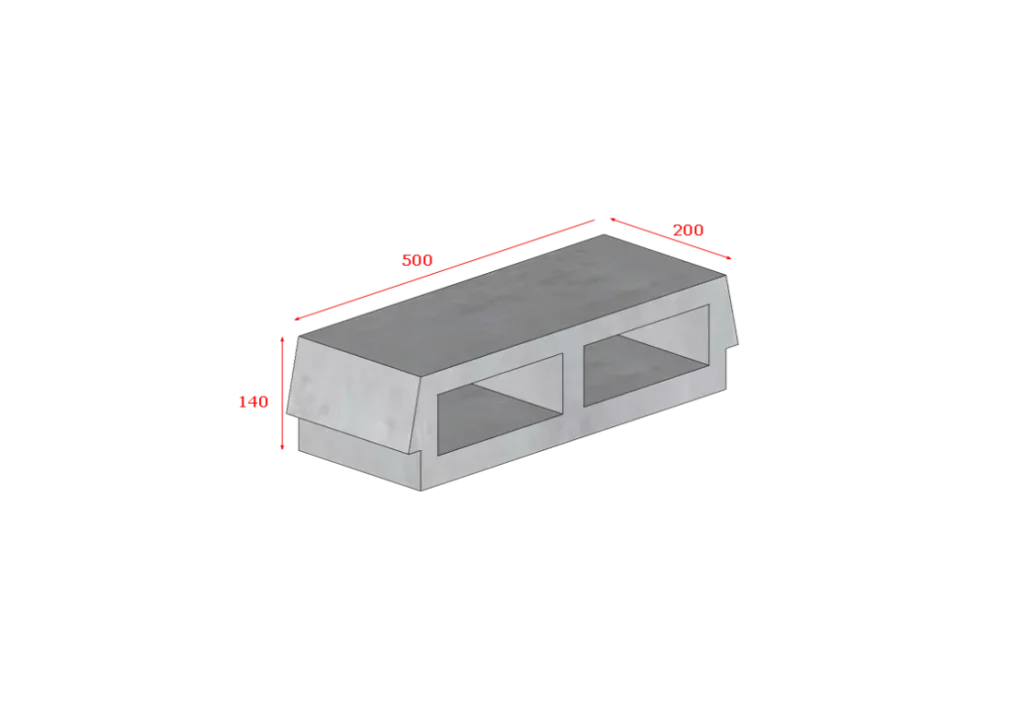

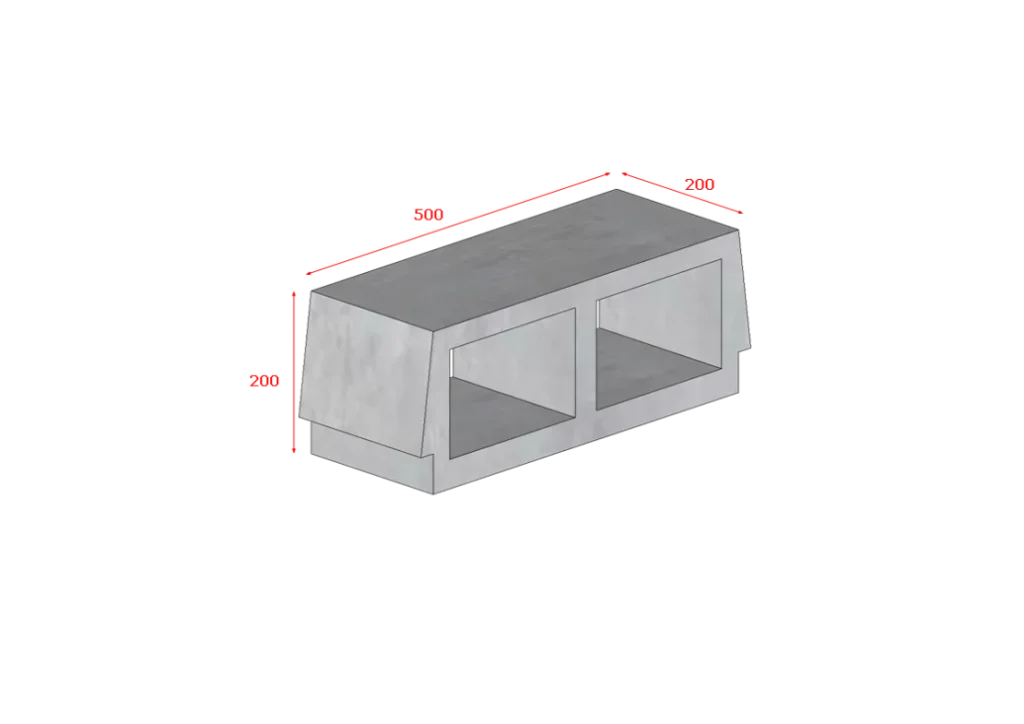

Ribs are put in place and supported with props. FT90/140/200 blocks are placed between the ribs and act as fillers (these replace the wooden formwork). Once all is in place additional steel mesh if fixed to the ribs and concrete is poured, and after a couple of weeks the props are removed. Ribs are manufactured in specified lengths to be placed over the required openings as designed by a qualified structural engineer.

- Product colour options -

The Rib & Block slab system is especially well-suited to the climate and architectural styles of the Garden Route, where fast and efficient construction methods are in high demand. At Mobicast, we proudly supply Rib & Block Garden Route systems in Mossel Bay, George, Groot Brakrivier, Knysna, Oudtshoorn, and surrounding areas. Our system is trusted by builders, developers, and engineers for its structural integrity, ease of installation, and cost-effectiveness. Whether you’re working on a residential project or a commercial development, Rib & Block in the Garden Route offers a reliable solution that saves both time and money without compromising on strength or quality.