HYDRANT BLOCK & LID

HYDRANT BLOCK & LID

We manufacture the Hydrant block and lid

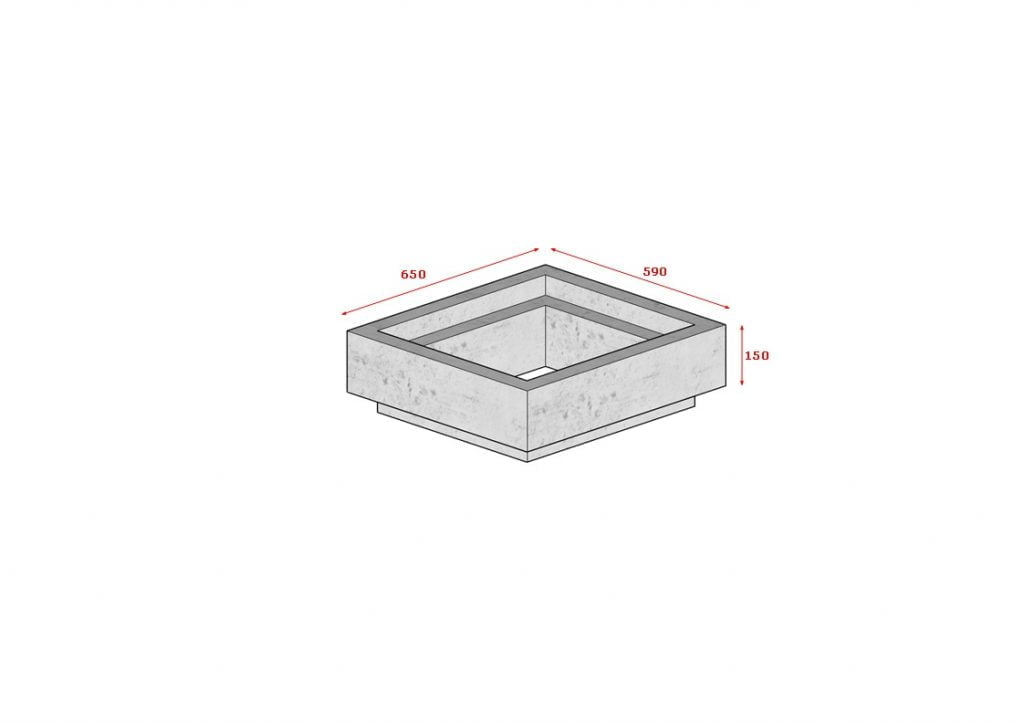

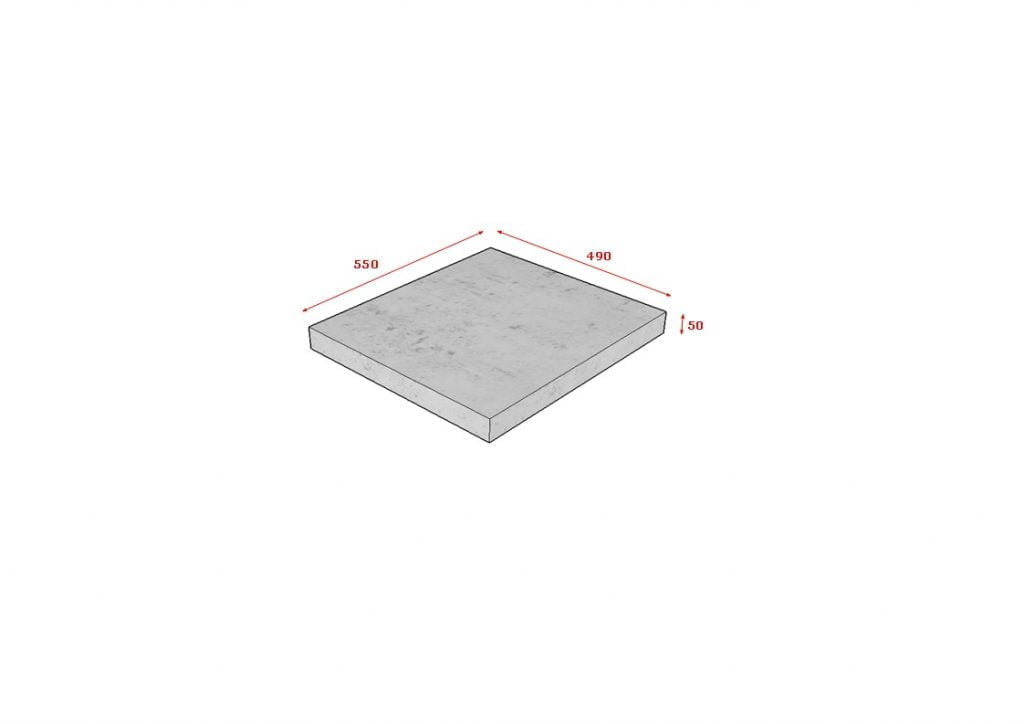

Hydrant Blocks are modular and fit on top of each other to create a cavity in which a hydrant is then placed.

Hydrant Blocks are modular and fit on top of each other to create a cavity in which a hydrant is then placed.

| Type | Dimensions (mm) | Mass |

|---|---|---|

| HYDRANT BLOCK | 650 x 590 x 150 | 75 kg |

| HYDRANT LID | 550x490x50 | 33 kg |

Hydrant Blocks are modular and fit on top of each other to create a cavity in which a hydrant is then placed.

- Product colour options -

- Product colour options -

Manufacturing fire hydrants is a crucial process that involves creating reliable and durable equipment for fire protection systems. Fire hydrants are essential for providing a readily available water source to firefighters during emergencies.

The manufacturing process begins with the selection of high-quality materials, such as cast iron or ductile iron, which are known for their strength and corrosion resistance. These materials are then melted and poured into molds to create the main body of the hydrant.

Once the hydrant body is formed, additional components such as valves, nozzles, and caps are added. These components are carefully designed to withstand high water pressure and ensure efficient water flow during firefighting operations.

Quality control measures are implemented throughout the manufacturing process to ensure that each fire hydrant meets industry standards and specifications. This includes rigorous testing for pressure resistance, leakage, and functionality.

Manufacturers also consider factors such as accessibility, visibility, and ease of maintenance when designing fire hydrants. These considerations ensure that fire hydrants are not only reliable but also user-friendly for firefighters and maintenance personnel.

In conclusion, manufacturing fire hydrants involves the use of high-quality materials, precise assembly of components, and rigorous testing to create reliable and efficient equipment for fire protection systems. The process prioritizes durability, functionality, and ease of maintenance to ensure that fire hydrants perform effectively during emergencies.