LöFFELSTEIN RETAINING BLOCKS

Löffelstein Retaining Blocks is a dry stacking, interlocking retaining system. It is unique because of its versatility, adaptability and plantability.

- Structurally stable – no need for additional concrete infill

- All Löffelstein retaining blocks are available in vertical and heavy duty applications

- Ideally suited for retaining cut or fill slopes between 3 and 15m high.

- Three basic block sizes – L300/L500.

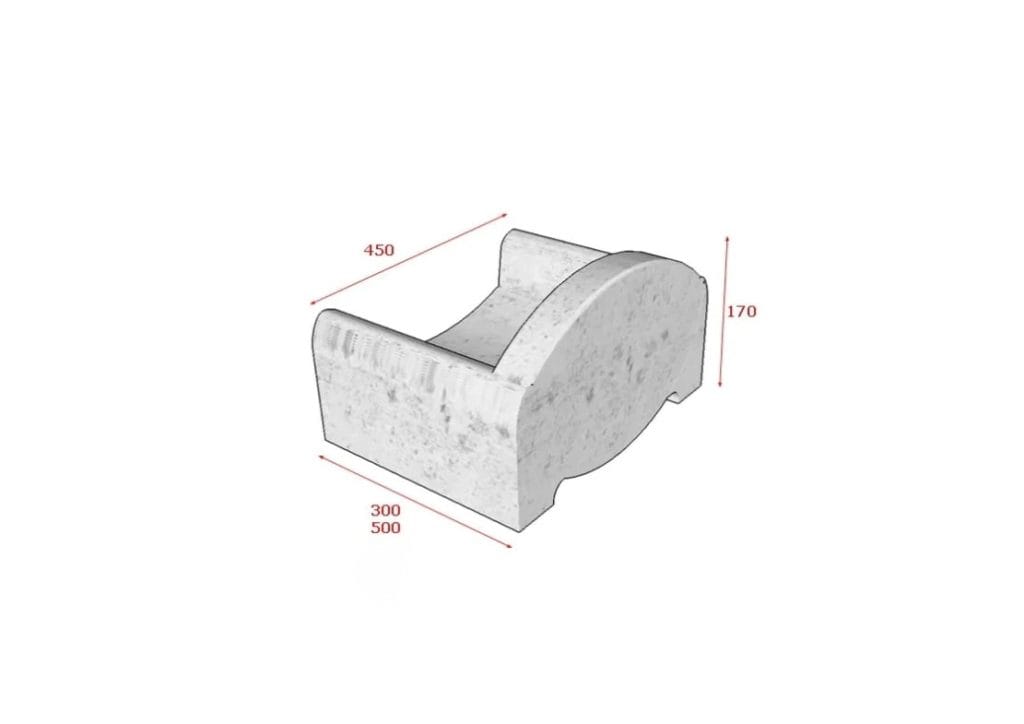

| Type | l300 | l500 |

|---|---|---|

| Length(mm) | 300 | 500 |

| Width(mm) | 450 | 450 |

| Height(mm) | 170 | 170 |

| Mass | 34 | 52 |

| No. blocks per linear meter | 1.6 | 1.6 |

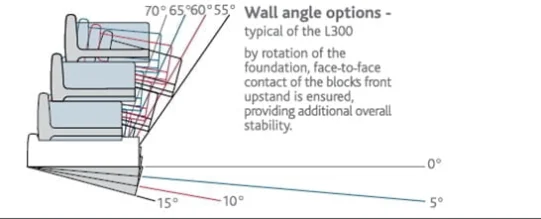

| Maximum wall angle | 70 degrees | 70 degrees |

| No. blocks per sqm straight line | 9.5 | 9.5 |

| Curved structures | 10-12 | 10-12 |

Foundations – must be designed to suit individual projects. Although in most instances where a wall is lower than 1.2 metres a simple concrete foundation will suffice, it is strongly advised that foundation design be carried out by a qualified engineer. Any retaining wall over 1.2 metres should both be engineered by, and have its construction supervised by a qualified engineer.

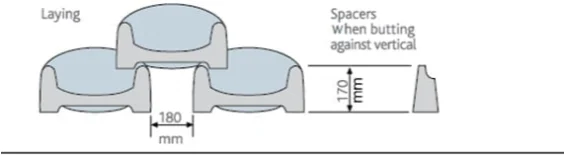

Laying – At 180mm spacings, lay the first course of blocks on the level base/angled base. Interlocking blocks of the second course are then centrally stacked to span two blocks of the lower course. Align the blocks horizontally with straight edge spirit level. Adjust minor level variations in blocks by trimming the higher sides with a chipping hammer. Align long straight lengths of walling by securing a fish line around outermost lying blocks and pulling the face of each block almost against the line. Fill preceding blocks with a suitable plant supportive soil. Correct compaction behind the blocks is critical and essential.

Curvatures – with the smallest possible radius of 2m for L300 and 3m for L500. Convex curvatures get smaller as an inclined structure rises. The first course is laid out to a maximum spacing of 190mm in the front and a corresponding smaller spacing at the back to suit the required radius. Concave curvatures get bigger as you build an inclined structure. Therefore, the first course is laid out with a minimum of spacing to suit the radius in the front and a correspondingly reduced spacing between the backs of the blocks. Depending on the accuracy of laying and the actual layout of curvatures, you may experience difficulties with the interlock or spacing of blocks after reaching a height of ±3m. To rectify this you should fill the completed preceding row of blocks with soilcrete, tamper it down hard and reset in accordance with the first course’s layout.

Technical Advice & Engineered Designs – The structural stability of a gravity retaining system depends on soil conditions, wall angle, overall slope stability and slope angle (surcharge) on top of the wall and base of wall. Again, please note that structures exceeding 1.2m in height necessitate engineered designs and the submission of plans to the local authority. Before construction, consider soil conditions, cohesion of material, overall slope stability, foundation requirements and choice of reinforcement.

Planting – completed structure. Take care in the choice of plants in order to minimise possible maintenance problems. Indigenous ground covers are recommended.